BDFU 1:3

Biodegradble Fibre Unit2014

When Iceland was first settled in the middle ages, the island was wooded “from the mountains to the sea,” but the impact of human habitation almost eliminated the woods within about 250 years. Systematic afforestation did not begin in Iceland until the early 1900s, and it has increased steadily ever since. It is predicted that within a few decades Iceland will become self-sufficient in timber production – as in recent years more trees have been planted per capita in Iceland than in most other countries.

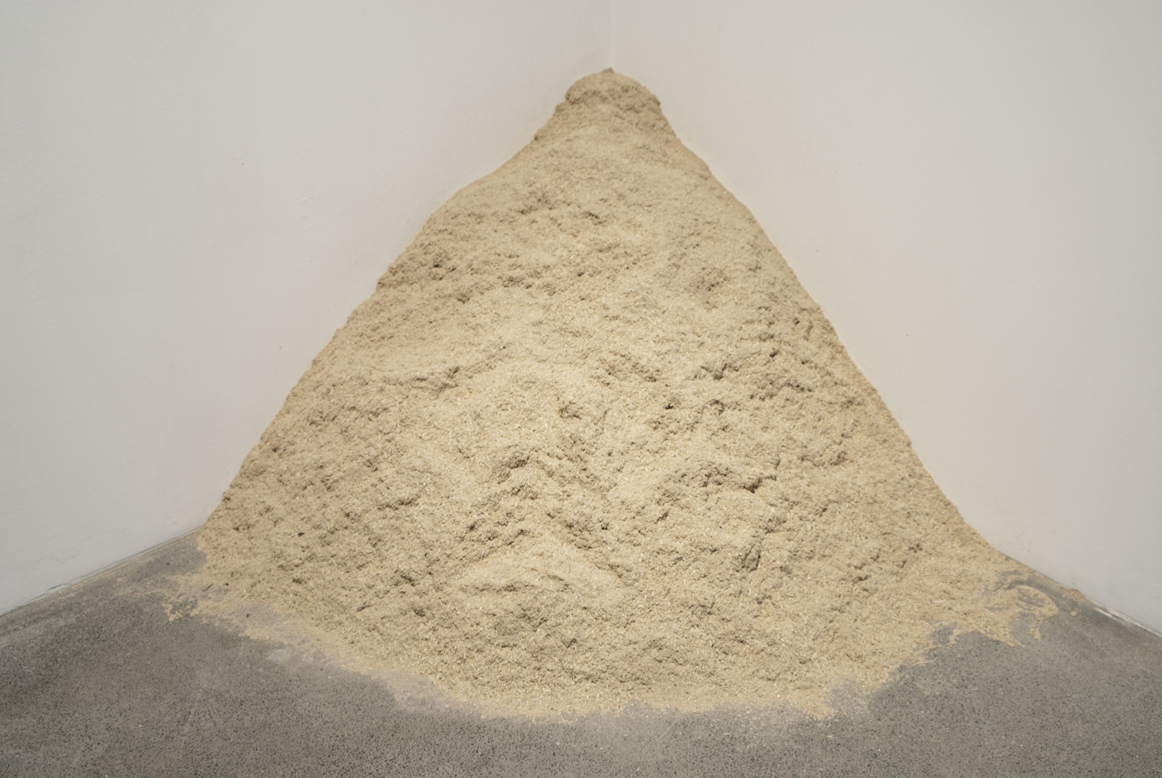

A problem that arises from timber production is that coppicing of woods produces quantities of wood and branches for which there is little use, other than chipping. This is especially true of Icelandic woods, where little of the wood can be utilised for boards or other useful timber.

By mixing wood chips with bioplastic made from natural substances, an entirely new material is made, which is light and strong, yet organic, so it will degrade rapidly in nature.

Not only is the added material environmentally friendly: the woodchips themselves are chipped using green energy from domestic sources. Woodchips are produced by Fengur Ltd. by a process using geothermal steam – hitherto the products have mainly been used as bedding for livestock. The new method enhances the value and potential applications for woodchips, as it produces a solid material that can be used for many purposes.

A problem that arises from timber production is that coppicing of woods produces quantities of wood and branches for which there is little use, other than chipping. This is especially true of Icelandic woods, where little of the wood can be utilised for boards or other useful timber.

By mixing wood chips with bioplastic made from natural substances, an entirely new material is made, which is light and strong, yet organic, so it will degrade rapidly in nature.

Not only is the added material environmentally friendly: the woodchips themselves are chipped using green energy from domestic sources. Woodchips are produced by Fengur Ltd. by a process using geothermal steam – hitherto the products have mainly been used as bedding for livestock. The new method enhances the value and potential applications for woodchips, as it produces a solid material that can be used for many purposes.